In recent years, the manufacturing landscape has witnessed a significant transformation, primarily driven by the advent of professional industrial large 3D printers. These advanced machines are not only enhancing production efficiency but also enabling unprecedented design flexibility. But what exactly makes these printers a game-changer in the industry?

Understanding Professional Industrial Large 3D Printers

A professional industrial large 3D printer is designed to produce large-scale components with high precision and speed. Unlike traditional manufacturing methods, which often involve multiple steps and processes, 3D printing allows for the creation of complex geometries in a single build. This capability reduces material waste and shortens lead times, making it an attractive option for various industries, including aerospace, automotive, and healthcare.

Key Advantages of Large-Scale 3D Printing

- Cost Efficiency: By minimizing material waste and reducing the need for extensive tooling, large 3D printers can significantly lower production costs.

- Design Flexibility: Engineers can create intricate designs that would be impossible to achieve with traditional methods.

- Rapid Prototyping: The ability to quickly produce prototypes accelerates the product development cycle.

- Customization: Large 3D printers allow for easy customization of products to meet specific client needs.

Applications of Professional Industrial Large 3D Printers

The versatility of professional industrial large 3D printers opens up a myriad of applications across different sectors. For instance, in the aerospace industry, these printers are used to create lightweight components that enhance fuel efficiency. In healthcare, they are revolutionizing the production of prosthetics and implants tailored to individual patients.

How to Choose the Right 3D Printer for Your Needs

When considering the acquisition of a professional industrial large 3D printer, several factors should be taken into account:

- Material Compatibility: Ensure the printer can handle the materials required for your projects.

- Build Volume: Assess the maximum size of parts you intend to produce.

- Print Speed: Evaluate the printer's speed to meet your production timelines.

- Support and Maintenance: Consider the manufacturer's support services and warranty options.

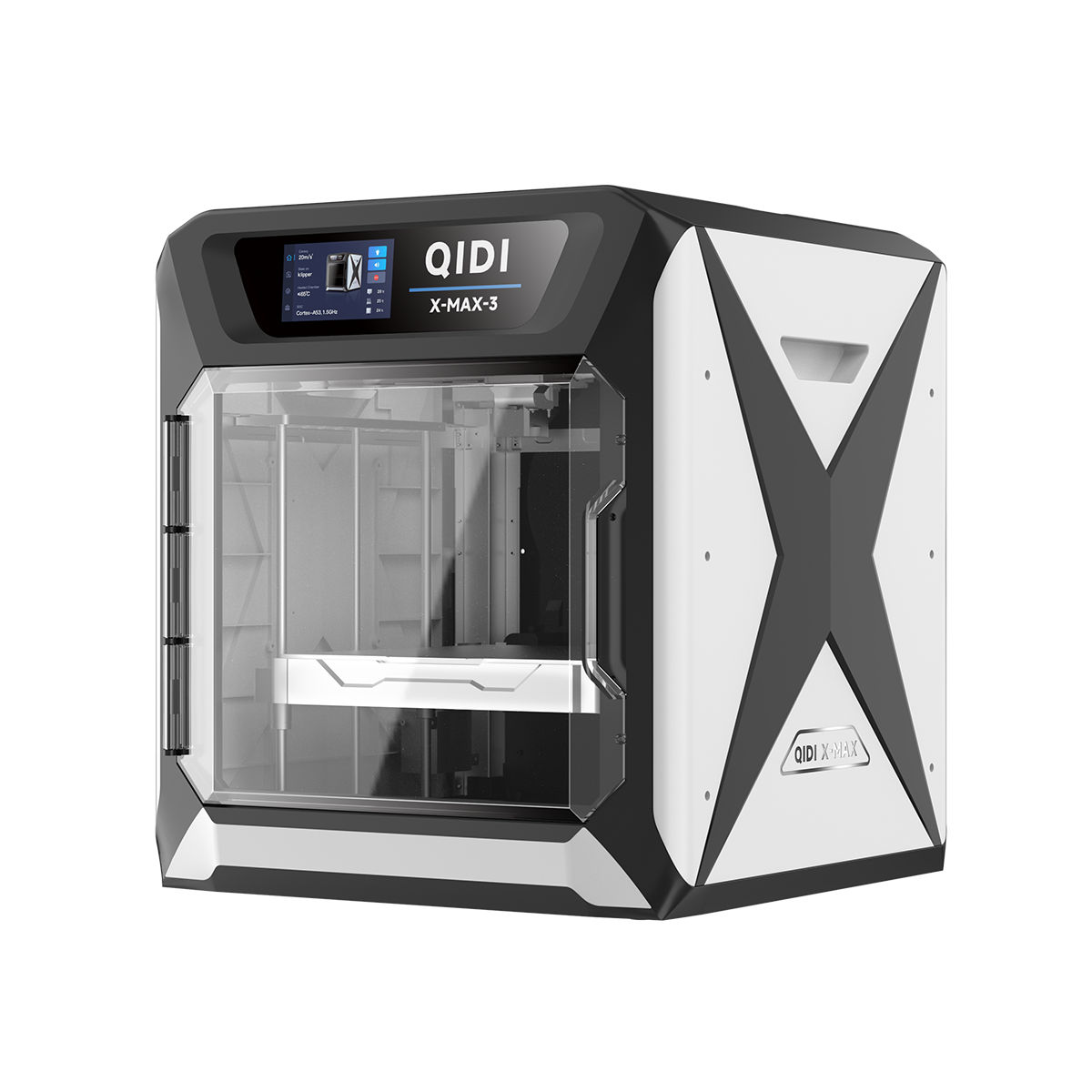

For those interested in exploring high-quality options, the  is a notable choice that combines performance with reliability.

is a notable choice that combines performance with reliability.

The Future of Manufacturing with 3D Printing

As we look ahead, the role of professional industrial large 3D printers in manufacturing will only continue to grow. With advancements in technology, we can expect even greater efficiency, sustainability, and innovation. Industries that embrace these changes will likely lead the way in the competitive global market.

In conclusion, the integration of professional industrial large 3D printers into manufacturing processes is not just a trend; it is a fundamental shift that is reshaping how products are designed and produced. As businesses adapt to these technologies, the potential for growth and innovation is limitless.