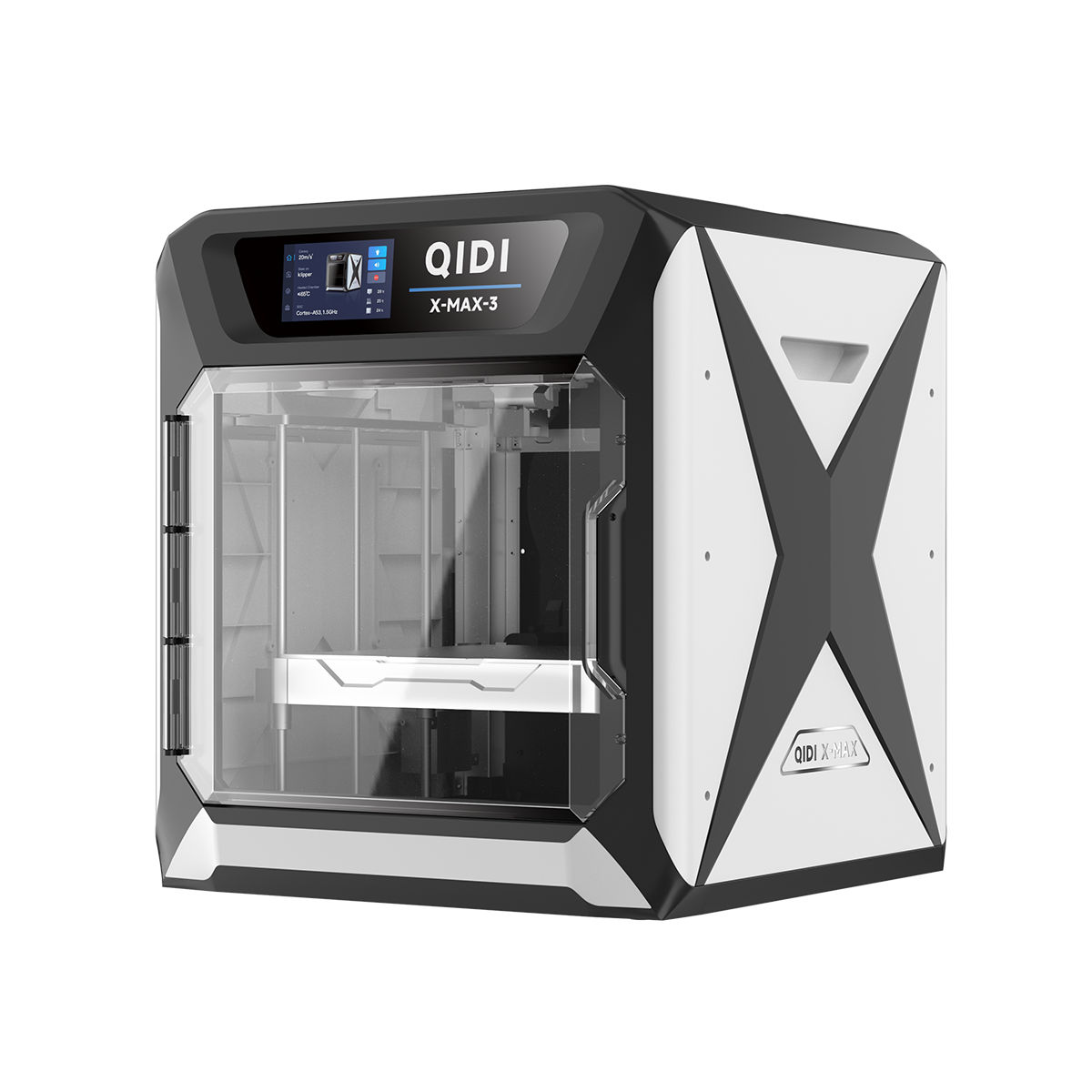

3D printing technology has been revolutionizing manufacturing processes across various industries. The advent of high-quality and large-scale 3D printers has significantly transformed the way products are designed, prototyped, and manufactured. In this article, we will delve into the impact of these advanced 3D printers on the manufacturing landscape and explore the game-changing benefits they offer.

The Evolution of 3D Printing

Revolutionizing Manufacturing: How High-Quality 3D Printers Are Changing the Game has come a long way since its inception. Initially used for rapid prototyping, 3D printing has evolved to encompass a wide range of applications, including end-use part production, tooling, and even construction. High-quality 3D printers have played a pivotal role in this evolution, enabling manufacturers to achieve unprecedented levels of precision, speed, and cost-efficiency in their production processes.

Enhanced Efficiency and Customization

One of the key advantages of high-quality and large-scale 3D printers is their ability to enhance efficiency and customization in manufacturing. These advanced 3D printers can produce complex geometries and intricate designs with ease, allowing for the creation of highly customized products that meet the specific needs of customers. Whether it's personalized medical implants or tailored automotive components, Revolutionizing Manufacturing: How High-Quality 3D Printers Are Changing the Game has opened up new possibilities for manufacturers to deliver bespoke solutions at scale.

Cost-Effective Production

Cost-effectiveness is another significant aspect of Revolutionizing Manufacturing: How High-Quality 3D Printers Are Changing the Game. By leveraging high-quality 3D printers, manufacturers can streamline their production processes, reduce material wastage, and minimize the need for expensive tooling equipment. This translates to lower production costs and faster time-to-market for new products. Additionally, the ability to consolidate multiple components into a single 3D-printed part can further drive down manufacturing expenses, making it a financially attractive option for businesses.

Industry Disruption and Innovation

The widespread adoption of high-quality and large-scale 3D printers has led to industry disruption and innovation across various sectors. From aerospace and automotive to healthcare and consumer goods, Revolutionizing Manufacturing: How High-Quality 3D Printers Are Changing the Game has empowered companies to rethink traditional manufacturing methods and explore new design possibilities. This has resulted in the development of lighter, stronger, and more efficient products that push the boundaries of what was previously thought possible.

In conclusion, the advent of high-quality and large-scale 3D printers has ushered in a new era of manufacturing capabilities. The impact of Revolutionizing Manufacturing: How High-Quality 3D Printers Are Changing the Game is undeniable, offering enhanced efficiency, cost-effective production, and unprecedented levels of customization. As technology continues to advance, we can expect further innovations in 3D printing that will continue to reshape the manufacturing landscape and drive future progress.