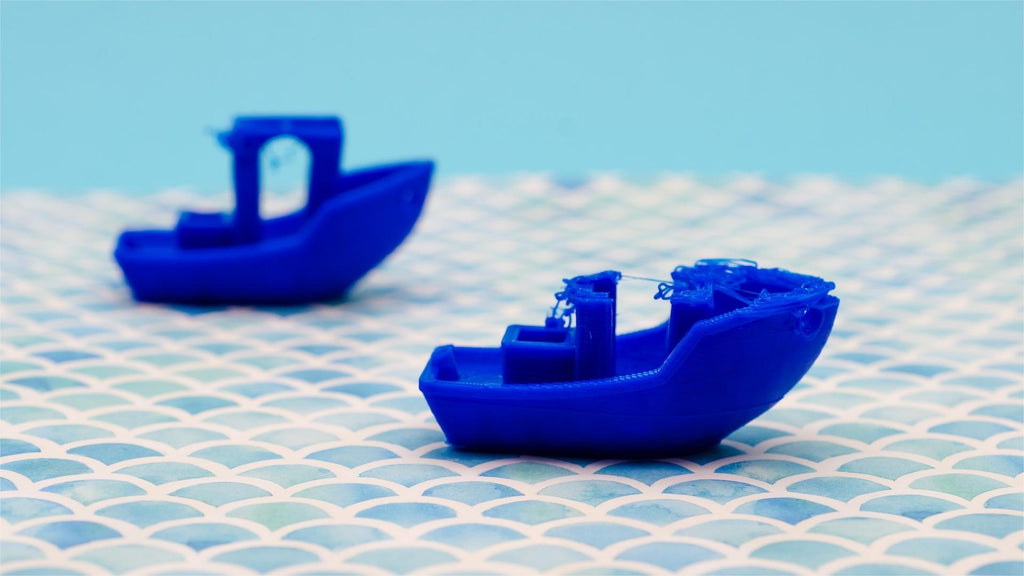

3D printing has revolutionized the way we create and manufacture objects. However, like any technology, it comes with its own set of challenges. This troubleshooting guide for 3D printing aims to help you identify and resolve the most common issues that may arise during the printing process.

Understanding Common 3D Printing Issues

Before diving into solutions, it's essential to understand the typical problems you might encounter. These issues can range from minor inconveniences to significant obstacles that hinder your printing experience. Here are some of the most frequently reported problems:

- Filament not sticking to the build plate

- Inconsistent extrusion

- Layer separation or warping

- Stringing and oozing

Filament Adhesion Problems

One of the most common issues in 3D printing is poor adhesion of the filament to the build plate. This can lead to failed prints and wasted materials. If you find that your prints are not sticking, consider the following:

"Proper bed leveling and surface preparation are crucial for successful prints."

Ensure that your build plate is level and clean. Using adhesives like glue sticks or specialized 3D printing adhesives can also enhance adhesion. If you are using a heated bed, adjusting the temperature can further improve results.

Inconsistent Extrusion: A Common Dilemma

Inconsistent extrusion can manifest as gaps in your print or uneven layers. This issue often stems from a clogged nozzle or improper filament feeding. To resolve this, check the following:

- Clean the nozzle to remove any blockages.

- Ensure that the filament is properly loaded and free from tangles.

- Adjust the extrusion multiplier settings in your slicer software.

Addressing Layer Separation and Warping

Layer separation and warping can occur due to rapid cooling or improper temperature settings. These issues can compromise the structural integrity of your print. To mitigate these problems, consider:

- Using an enclosure to maintain a stable temperature.

- Adjusting the print speed and temperature settings.

- Choosing the right filament type for your project.

Dealing with Stringing and Oozing

Stringing and oozing can lead to unsightly artifacts on your prints. This issue is often caused by excessive heat or incorrect retraction settings. To fix this, you can:

"Fine-tuning your retraction settings can significantly reduce stringing."

Experiment with retraction distance and speed in your slicer software. Additionally, lowering the printing temperature can help minimize oozing.

Conclusion: Your Go-To Troubleshooting Guide for 3D Printing

By understanding these common issues and their solutions, you can enhance your 3D printing experience. Remember, troubleshooting is an integral part of the process, and with practice, you will become more adept at resolving these challenges. For more detailed guidance, consider exploring resources like this troubleshooting guide for 3D printing.

References