The construction industry is on the brink of a significant transformation, driven by advancements in technology. One of the most promising innovations is 3D printed sand, which is reshaping how we think about building materials and processes. This article delves into the implications of this technology, exploring its benefits, applications, and future potential.

What is 3D Printed Sand?

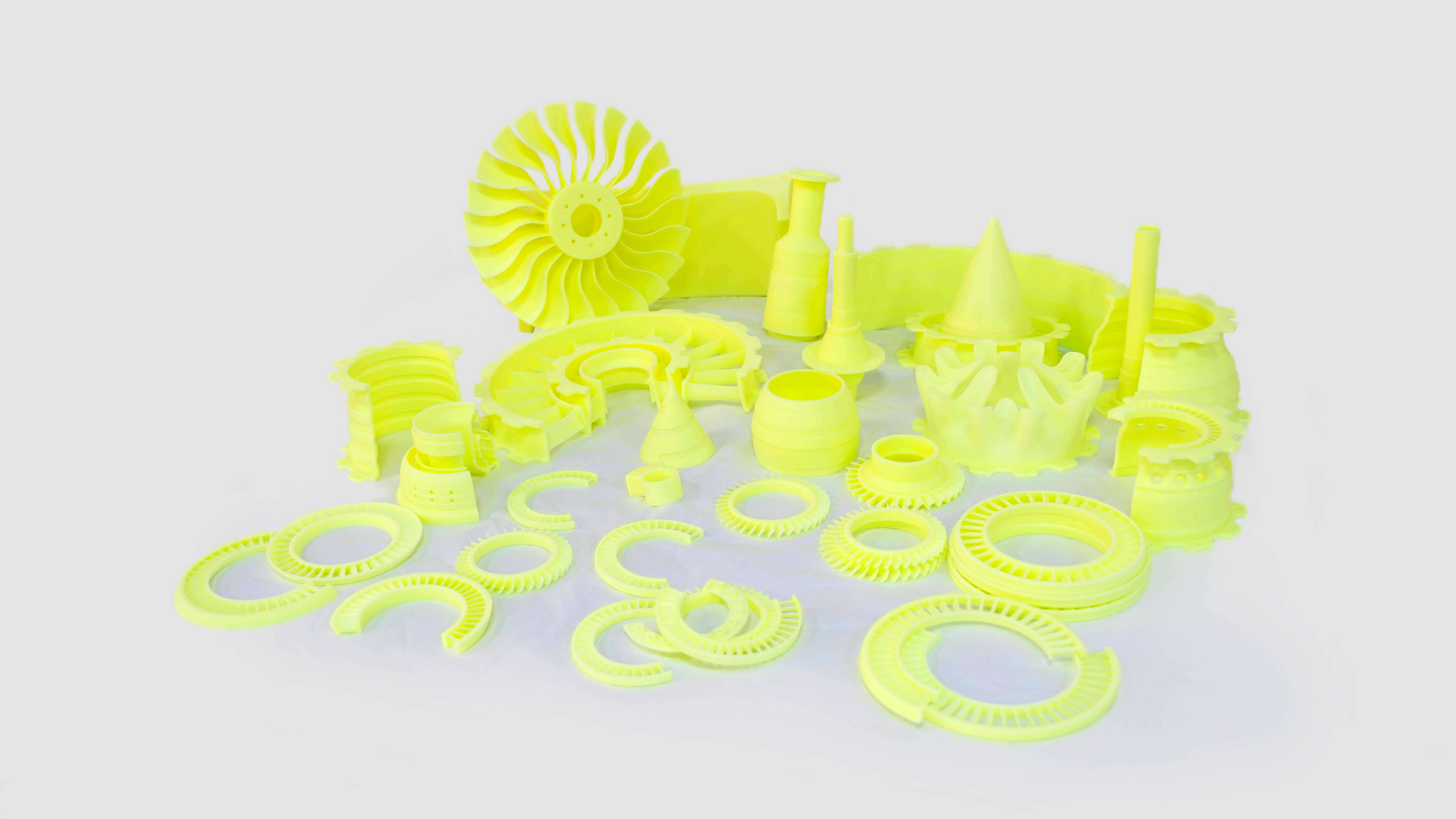

3D printed sand refers to a process where sand is used as a primary material in 3D printing to create molds and structures. This method employs a binder jetting technique, where a liquid binder is selectively deposited onto layers of sand, solidifying them into a desired shape. The result is a highly customizable and efficient building solution.

Benefits of Using 3D Printed Sand

- Sustainability: Traditional construction methods often lead to significant waste. In contrast, 3D printed sand minimizes material waste, making it an eco-friendly option.

- Cost-Effectiveness: By reducing labor and material costs, 3D printed sand can lead to lower overall project expenses.

- Design Flexibility: This technology allows for intricate designs that would be challenging or impossible to achieve with conventional methods.

Applications of 3D Printed Sand in Construction

The versatility of 3D printed sand opens up numerous applications in the construction industry. From creating complex architectural features to producing molds for concrete casting, the possibilities are vast. For instance, companies are now using this technology to build:

- Custom sculptures and art installations

- Architectural prototypes for client presentations

- Functional building components, such as facades and walls

"3D printed sand is not just a trend; it's a game-changer for the construction industry, enabling us to rethink how we build." - Industry Expert

Challenges and Considerations

While the benefits of 3D printed sand are compelling, there are challenges to consider. The technology is still evolving, and factors such as material properties, structural integrity, and regulatory compliance need to be addressed. However, ongoing research and development are paving the way for solutions to these challenges.

The Future of 3D Printed Sand in Construction

Looking ahead, the future of 3D printed sand appears bright. As the technology matures, we can expect to see increased adoption across various sectors of the construction industry. Innovations in materials and printing techniques will likely enhance the performance and applicability of this method. Furthermore, as sustainability becomes a priority, the demand for eco-friendly construction solutions will drive the growth of 3D printed sand.

For more insights into this revolutionary technology, check out this informative video: Watch Now.

In conclusion, 3D printed sand is not just a fleeting trend; it represents a significant shift in how we approach construction. By embracing this technology, we can create a more sustainable, efficient, and innovative building industry.