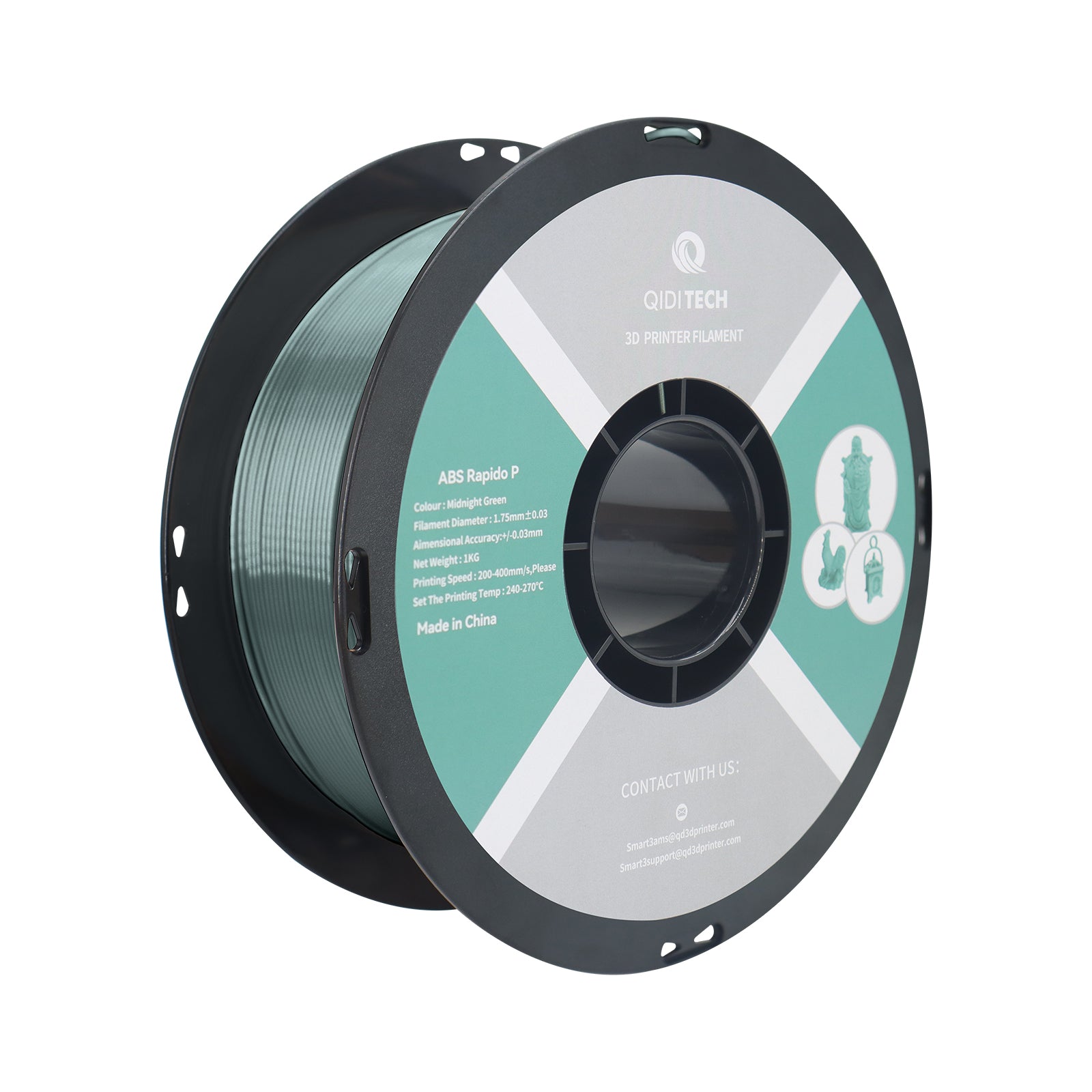

When it comes to 3D printing, the choice of filament can significantly impact the quality and durability of your final product. Among the various options available, heat resistant ABS filament for 3D printing projects stands out for its exceptional properties. This article will explore the advantages of using this specialized filament and why it may be the ideal choice for your next project.

Understanding Heat Resistant ABS Filament

Heat resistant ABS filament is a modified version of standard ABS (Acrylonitrile Butadiene Styrene) that has been engineered to withstand higher temperatures. This makes it suitable for applications where thermal stability is crucial. But what exactly makes this filament different? The key lies in its formulation, which enhances its thermal resistance while maintaining the inherent benefits of traditional ABS, such as strength and flexibility.

Advantages of Heat Resistant ABS Filament for 3D Printing Projects

- Enhanced Thermal Stability: One of the primary benefits of using heat resistant ABS filament for 3D printing projects is its ability to endure elevated temperatures without deforming. This property is essential for parts that will be exposed to heat, such as automotive components or household items near heat sources.

- Improved Mechanical Properties: This filament not only resists heat but also offers superior impact resistance and tensile strength compared to standard ABS. This means that your printed objects will be more durable and less likely to break under stress.

- Versatility: Heat resistant ABS is suitable for a wide range of applications, from prototypes to functional parts. Whether you are creating intricate designs or robust components, this filament can meet your needs.

- Easy to Print: Despite its enhanced properties, heat resistant ABS filament for 3D printing projects is relatively easy to work with. It adheres well to the print bed and can be printed at standard ABS temperatures, making it accessible for both beginners and experienced users.

Applications of Heat Resistant ABS Filament

So, where can you use heat resistant ABS filament for 3D printing projects? The possibilities are vast. Here are some common applications:

- Automotive parts, such as brackets and housings.

- Household items, including kitchen tools and appliance components.

- Industrial applications, such as jigs and fixtures.

- Prototyping for products that require heat resistance.

Making the Switch to Heat Resistant ABS Filament

If you are considering a switch to heat resistant ABS filament for 3D printing projects, it is essential to choose a reliable supplier. For high-quality options, you can explore . This filament not only meets the demands of high-performance applications but also ensures that your projects achieve the best possible results.

In conclusion, the benefits of using heat resistant ABS filament for 3D printing projects are clear. With its enhanced thermal stability, improved mechanical properties, and versatility, it is an excellent choice for a variety of applications. By making the switch, you can elevate the quality and durability of your 3D printed objects.