In recent years, the advent of precision and large scale 3D printers has significantly transformed the landscape of manufacturing. These advanced machines are not only enhancing production capabilities but also redefining the very essence of how products are designed and created. This blog post delves into the remarkable impact of these technologies on various industries.

Understanding Precision in 3D Printing

Precision is a critical factor in 3D printing, especially when it comes to applications that demand high accuracy. How does precision influence the quality of printed objects? The answer lies in the technology used. High-resolution printers can produce intricate designs with minimal tolerances, ensuring that the final product meets stringent specifications.

- Enhanced detail in prototypes

- Improved fit and function in end-use parts

- Reduction in material waste

For industries such as aerospace and medical devices, where even the slightest deviation can lead to catastrophic failures, precision is paramount. The ability to create complex geometries with exacting standards opens up new possibilities for innovation.

Large Scale 3D Printing: A Game Changer

Large scale 3D printers are revolutionizing manufacturing by enabling the production of substantial components that were previously impossible to create using traditional methods. What are the advantages of large scale 3D printing? Here are a few key benefits:

- Cost-effective production of large parts

- Reduced lead times for manufacturing

- Ability to create customized solutions for specific projects

Industries such as construction and automotive are leveraging large scale 3D printing to fabricate everything from building components to entire vehicle parts. This shift not only streamlines the manufacturing process but also promotes sustainability by minimizing waste.

Applications Across Industries

The versatility of precision and large scale 3D printers allows them to be utilized across various sectors. Here are some notable applications:

- Aerospace: Lightweight components that enhance fuel efficiency.

- Healthcare: Custom prosthetics and implants tailored to individual patients.

- Automotive: Rapid prototyping and production of complex parts.

- Construction: 3D printed homes and structures that reduce labor costs.

As these technologies continue to evolve, we can expect even more innovative applications to emerge, further solidifying the role of 3D printing in modern manufacturing.

Conclusion: Embracing the Future of Manufacturing

The integration of precision and large scale 3D printers into manufacturing processes is not merely a trend; it is a fundamental shift that is reshaping industries. Companies that embrace these technologies will not only enhance their production capabilities but also gain a competitive edge in the market.

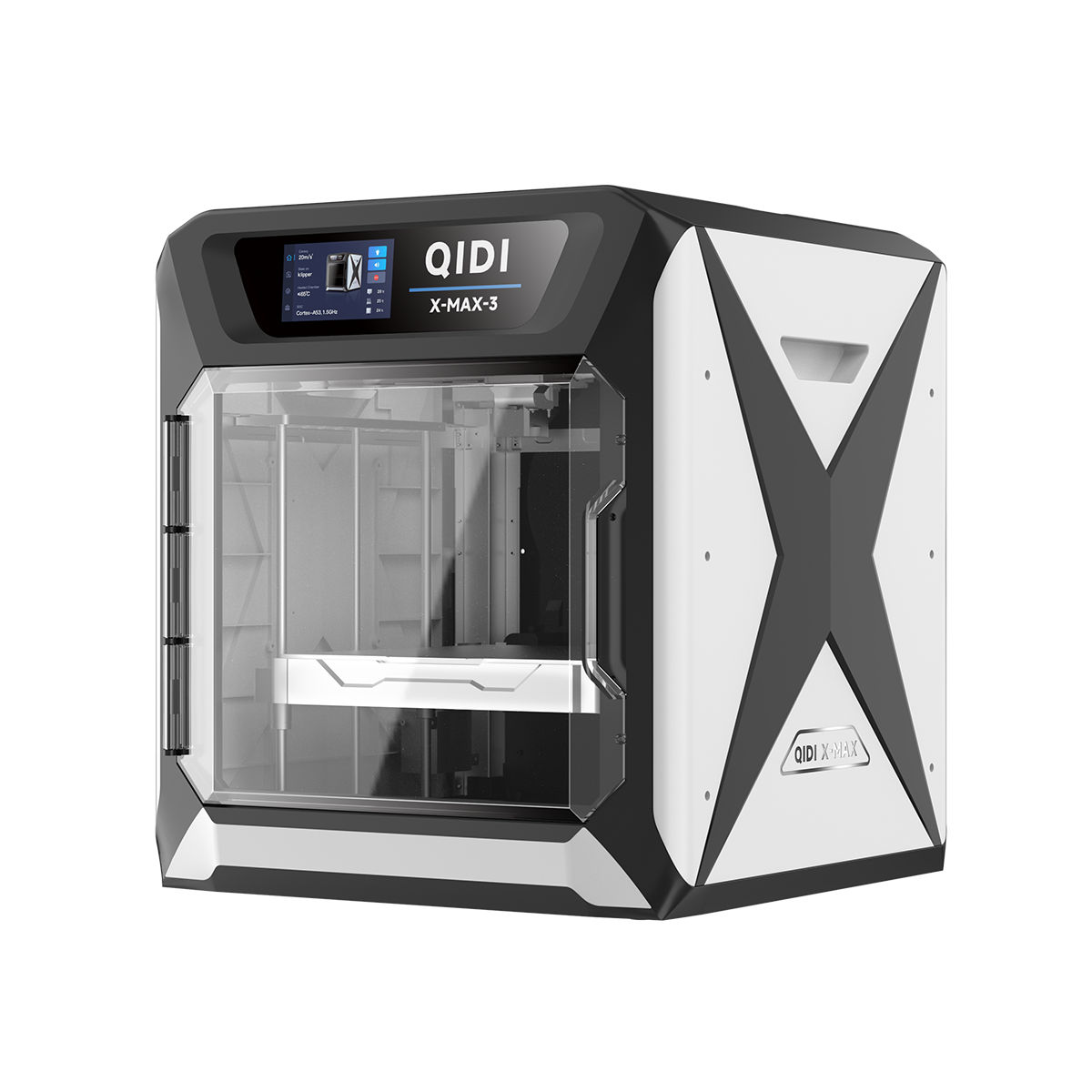

For those interested in exploring high-quality 3D printing solutions, consider checking out the  . This printer exemplifies the precision and large scale capabilities that are essential for modern manufacturing.

. This printer exemplifies the precision and large scale capabilities that are essential for modern manufacturing.