Calibration Woes

One of the most frequent challenges that 3D printing enthusiasts encounter is calibration issues. When your printer is not properly calibrated, it can lead to misaligned layers, poor adhesion, and overall print quality. To address this, ensure that your printer's bed is leveled correctly. Use a leveling tool to make adjustments until the bed is perfectly aligned. Additionally, check the extruder's temperature and filament flow to guarantee smooth printing.

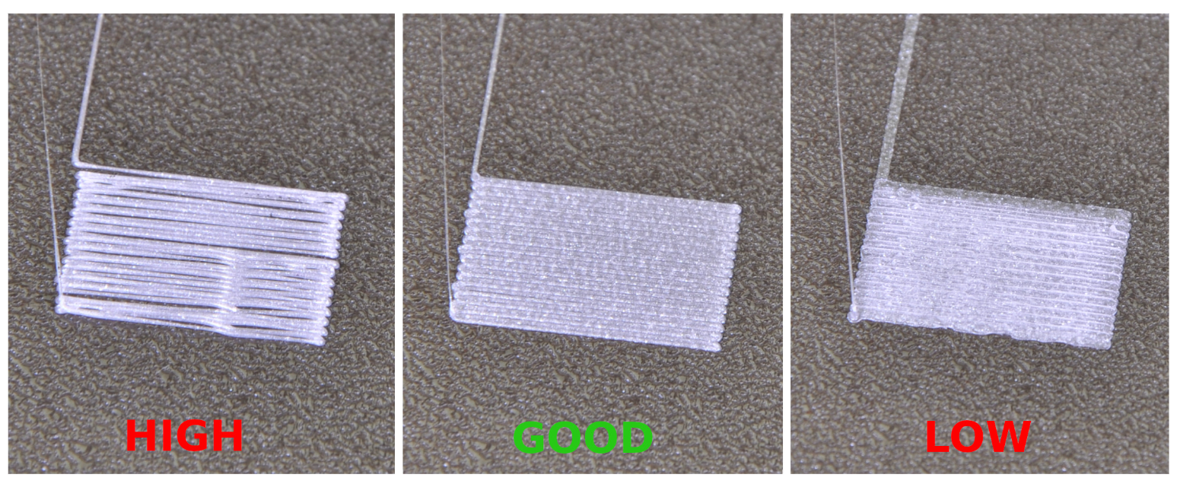

Extrusion Problems

Another common issue faced by 3D printing hobbyists is extrusion problems. This can manifest as under-extrusion, over-extrusion, or inconsistent extrusion throughout the print. To troubleshoot this, start by examining the filament path for any obstructions or tangles. Adjust the extrusion multiplier in your slicer software to regulate the flow of filament. It's also advisable to clean the extruder nozzle regularly to prevent clogs.

Warped Prints

Warped prints are a frustrating setback that many 3D printing enthusiasts encounter, especially when printing larger objects. Warping occurs when the corners of a print lift off the bed during the printing process. To combat this issue, ensure that your print bed is heated to the appropriate temperature for the filament being used. Additionally, applying a brim or raft around the base of your print can provide extra adhesion and prevent warping.

Layer Adhesion Challenges

Layer adhesion problems can result in weak, brittle prints that are prone to breaking. This issue is often caused by inadequate bed adhesion or improper cooling settings. To enhance layer adhesion, adjust your print bed's temperature based on the filament type. Increasing the bed temperature can promote better adhesion between layers. Moreover, optimizing your printer's cooling fan settings can prevent overheating and improve layer bonding.

Stringing and Oozing

Stringing and oozing refer to the thin strands of filament that appear between different parts of your print, leading to a messy finish. To address this issue, fine-tune your retraction settings in the slicer software. Increasing the retraction distance and speed can help minimize stringing. Additionally, adjusting the printing temperature and travel speed can also reduce oozing and improve the overall print quality.

By familiarizing yourself with these 5 common 3D printing problems and implementing the suggested solutions, you can troubleshoot issues like a pro and achieve high-quality prints consistently. Remember, patience and attention to detail are key when it comes to mastering the art of 3D printing!